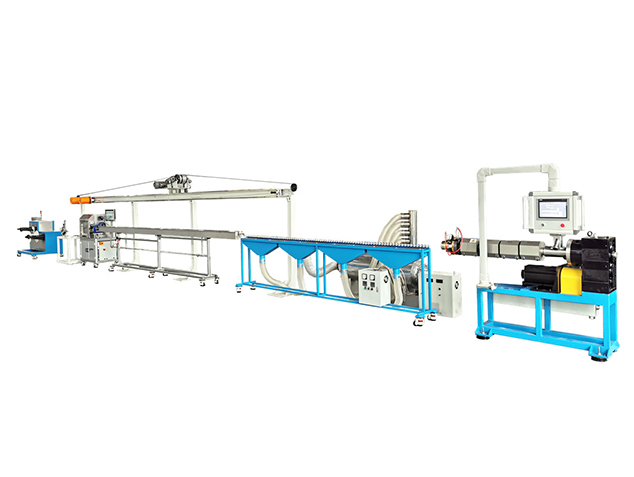

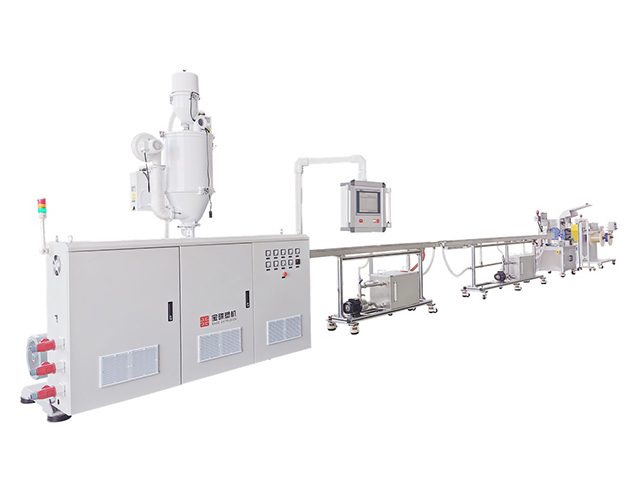

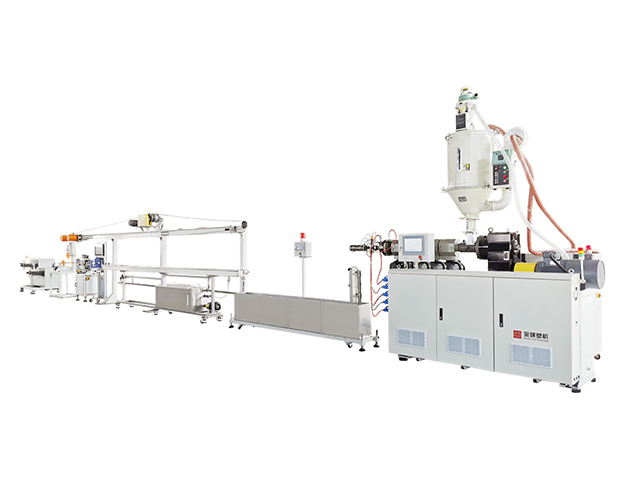

3D Printer Filament Extrusion Line (Air Cooling)

-

Lebelo la tlhahiso:

DN1.75mm 120-150m/min, DN3.0mm 45-55m/min.

-

Ho nepahala ha sehlahisoa:

2.9mm-3.0mm, 1.70-1.80mm. (Boholo +/-0.05mm, karolelano +/-0.03mm, CPK ≥1.6).

Tlhahisoleseding ya Sehlahiswa

Ka ho tsebahala le ho sebelisoa ha theknoloji ea khatiso ea 3D, e thehiloeng motheong oa lisebelisoa tse tloaelehileng tsa PLA le ABS, nts'etsopele le ts'ebeliso ea lisebelisoa tse khethehileng tse nang le ts'ebetso e ntle le tsona li ntlafatsoa butle-butle, tse kang PEEK le PVA. PEEK (polyether ether ketone) ke mofuta oa polasetiki e khethehileng ea boenjiniere e nang le khanyetso e phahameng ea mocheso, ho itšehla thajana, ho sebetsa habonolo le matla a phahameng a mochine le thepa e meng e babatsehang. E ka etsoa le ho sebetsoa ka likarolo tse fapaneng tsa mochini, joalo ka lisebelisoa tsa koloi, skrini sa oli, poleiti ea ho qala ea shift; Likarolo tsa enjene ea sefofane, lebili la mochini o hlatsoang o ikemetseng, likarolo tsa lisebelisoa tsa bongaka, joalo-joalo. PEEK ts'ebetso e ntle haholo e kopantsoeng le theknoloji ea khatiso ea 3D, e tla sebelisoa haholo indastering ea likoloi, lifofane, tsa bongaka le tse ling ts'ebetsong ea phetisetso ho thata haholo ho fihlela litlhoko tsa ts'ebetso ea likarolo. .

Ea ronamolemo

Litšobotsi tsa Line ea Tlhahiso

- Mohala oohle o na le koloi e feletseng ea SERVO ho netefatsa ts'ebetso e tsitsitseng ea khokahanyo e 'ngoe le e' ngoe ea thekenoloji ea extrusion, e kang ho tsoa, ho lekanya ho qhibiliha, ho hula, joalo-joalo;

- Amohela heater ea koporo, e ka fihlelang mocheso oa extrusion ho fihla ho 500 ℃;

- E na le sistimi ea pompo ea metering, ho netefatsa ho nepahala ha extrusion ea lintho tse qhibilihisang, eketsa khatello ea hlooho ea lefu ho qoba sekoti kahare;

- Moralo o ikhethileng oa tanka e sebetsang ea ho futhumatsa moea o chesang, e loketseng lisebelisoa tsa mocheso o phahameng oa PEEK, mokhoa oa ho bopa o qhibilihang ka metsi oa PVA;

- E na le tlhahlobo ea OD ea inthaneteng le ts'ebetso ea ho laola maikutlo ka boiketsetso, mamello ea boemo ba sehlahisoa e laoloa ho isa bonyaneng ho ntlafatsa boemo ba othomathike ba mohala kaofela;

- Taolo ea lenaneo la Servo wiring traverse + PLC ho fihlella ho nepahala ha marang-rang le ho koloka ka makhethe, li-spool tse kholo le tse nyane li ka sebelisoa bakeng sa matsoelintsoeke a makhethe.