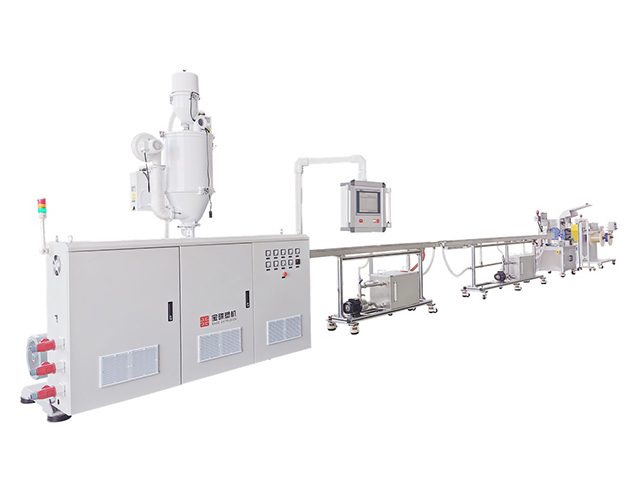

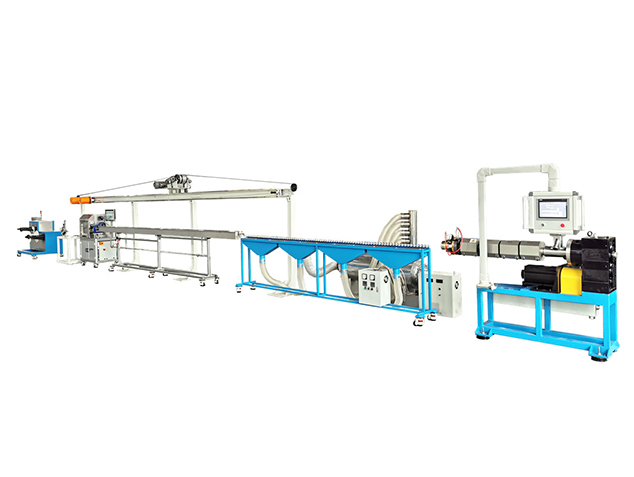

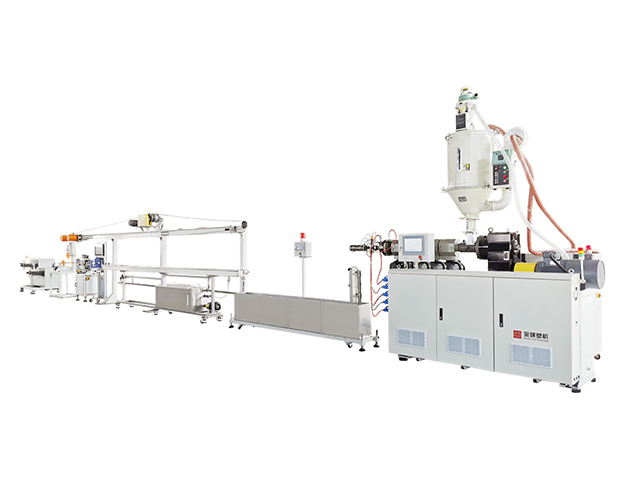

3D Printer Filament Extrusion Line (Mofuta o Tloaelehileng)

-

Lebelo la tlhahiso:

DN1.75mm 120-150m/min, DN3.0mm 45-55m/min.

-

Laola ho nepahala:

Φ3.0 limilimithara ho 2.9 limilimithara, 1.70 ho 1.80 limilimithara. (Max ≤± 0.04mm, Karolelano≤± 0.03mm, CPK≥1.6).

Tlhahisoleseding ya Sehlahiswa

Sebopeho sa terata ea polasetiki ea khatiso ea 3D ke terata e pota-potileng e tiileng hona joale, thepa e ka sehloohong e tala e na le PLA, PVA, HIPS, ABS, PC, PA, TPU joalo-joalo, lihlahisoa li tloha ho 1.75 mm ho ea ho 3.0 mm bophara. BAOD EXTRUSION e fane ka mochini oa pele oa 3D PRINTER FILAMENT extrusion mochini ho bareki ka 2009, kamora nako e telele e tsoelang pele ea ntlafatso ea tlhophiso ea lisebelisoa le theknoloji ea extrusion, re thehile sete ea lisebelisoa tse ikhethileng tsa 3D printing consumables extrusion line, e ts'oanang le sekoaelo se fapaneng. die molding thekenoloji, e ka khotsofatsang ka mefuta e fapaneng ea tlhahiso ea thepa.

Ea ronamolemo

Features Of Machine Line

1. Full SERVO drivingis e hlomelloa mocheng oohle oa mochine, e lebisa ho ts'ebetsong e tsitsitseng e phahameng bakeng sa likarolo ka 'ngoe holim'a li-extrusion line, tse kang ho qhibiliha extruding, ho qhibiliha metering, ho hula, joalo-joalo;

2. E na le tsamaiso ea pompo ea metering, e habeli e netefatsa ho nepahala ha phallo ea ho qhibiliha, ho sa le joalo eketsa khatello ea hlooho ea lefu ho qoba sekoti ka hare ho terata;

3. E na le laser gauge ea marang-rang ea bophara ba marang-rang le ts'ebetso ea ho laola maikutlo a boiketsetso, laola mamello ea boholo ho boleng bo tlase, phahamisa boemo ba line automation kaofela;

4. Ho tsubella le ho feta ka taolo ea lenaneo la SERVO drive & PLC ho hlokomela marang-rang a nepahetseng le a hlophisehileng (a makhethe) a matsoelintsoeke a fumanehang bakeng sa spool e kholo le e nyane.