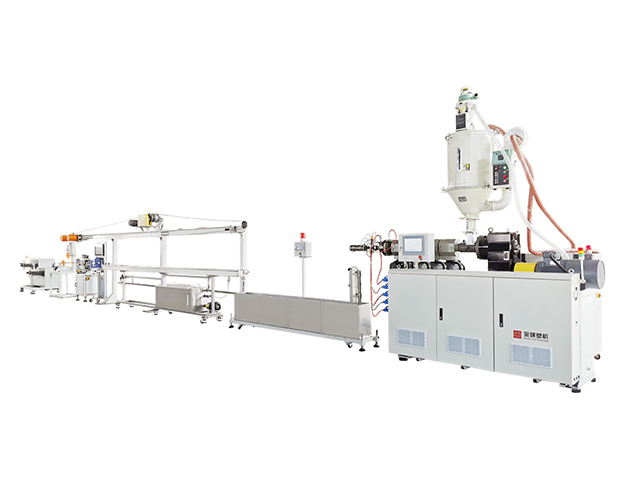

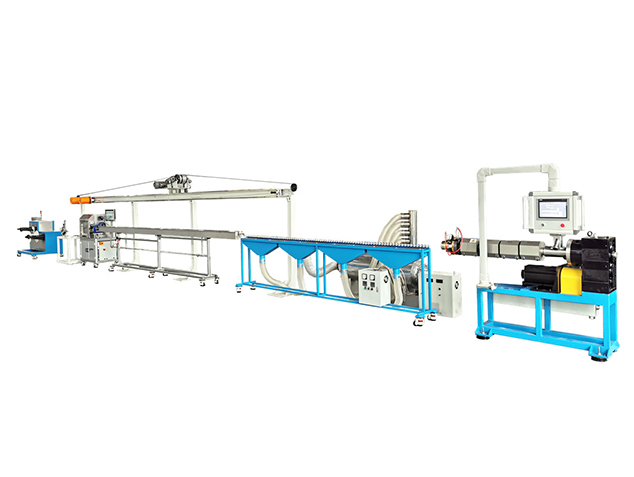

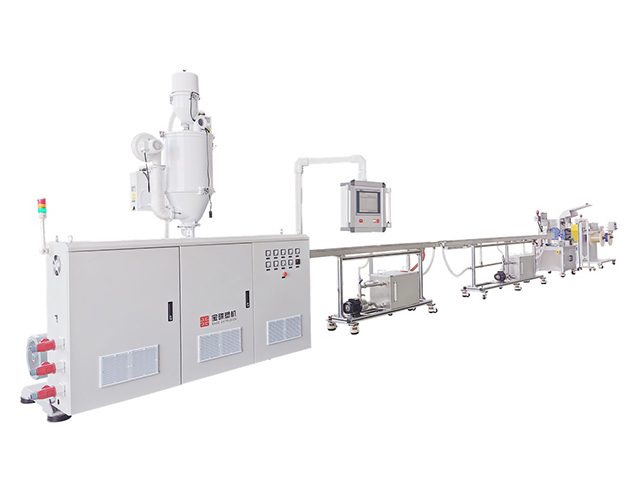

3D Printer Filament Extrusion Line (Vertical Calibration)

-

Lebelo la tlhahiso:

DN1.75mm 120-150m/min, DN3.0mm 45-55m/min.

-

Laola ho nepahala:

Φ3.0 limilimithara ho 2.9 limilimithara, 1.70 ho 1.80 limilimithara. (Boholo +/-0.04mm, Karolelano +/-0.03mm, CPK≥1.6)

Tlhahisoleseding ya Sehlahiswa

Sebopeho sa terata ea polasetiki ea khatiso ea 3D ke terata e pota-potileng e tiileng hona joale, thepa e ka sehloohong e tala e na le PLA, PVA, HIPS, ABS, PC, PA, TPU joalo-joalo, lihlahisoa li tloha ho 1.75 mm ho ea ho 3.0 mm bophara. BAOD EXTRUSION e fane ka sete ea pele ea mochini oa extrusion oa 3D PRINTER FILAMENT ho moreki ka 2009. Kamora nako e telele ea liteko le netefatso, re fumane hore bakeng sa lisebelisoa tse phahameng tsa ho qhibiliha ha polymer (tse kang TPU, PA, PC, joalo-joalo) ka ho otloloha. mokhoa oa ho lokisa ho pholile, boholo ba ho theha (haholo-holo ellipticity) ea filament bo ntlafalitsoe haholo. Ho ikamahanya le maemo ha 3D printer filament extrusion process ho thepa ho ntse ho atolosoa.

Ea ronamolemo

Features Of Machine Line

1. Ho khanna ka servo ka botlalo ho hlomelloa mocheng oohle oa mochini, ho lebisa mathateng a phahameng a tsitsitseng bakeng sa likarolo ka 'ngoe holim'a mohala oa extrusion, joalo ka melt extruding, melt metering, hula, joalo-joalo;

2. Ho na le tsamaiso ea pompo ea metering, ho netefatsa habeli ho nepahala ha phallo ea ho qhibiliha, ho sa le joalo eketsa khatello ea hlooho ea lefu ho qoba sekoti ka hare ho terata;

3. E na le laser gauge ea marang-rang ea bophara ba marang-rang le ts'ebetso ea ho laola maikutlo a boiketsetso, laola mamello ea boholo ho boleng bo tlase, phahamisa boemo ba line automation kaofela;

4. Winding and Traversing by SERVO drive & PLC program control to realise online precially and orderly order (makhethe) matsoelintsoeke, matsoelintsoeke fumaneha bakeng sa tse peli tse khōlō le tse nyenyane spool.